When economic difficulties hit, leaders’ Lean Management techniques become more popular — allowing companies to create high value products at lower cost while maintaining high quality. The advantages for manufacturing are well known, but do they translate to database marketing and marketing analytics operations?

Database marketing can be said to be the manufacturer of information. Customer data (raw material) is consolidated, run through data quality procedures (machinery), and then moved into a data warehouse. Data is withdrawn from the warehouse by craftspeople who perform analytics so that marketing campaigns can be initiated (finished goods). When considering database marketing from the viewpoint of a manufacturing operation, lean makes complete sense. Let’s look at how lean works in marketing organizations.

I have performed a Lean training event for the past five years for our marketing technology team. We compare traditional ad hoc data processing with lean processes. Consistently, lean cuts 60 to 80 percent of the time, effort, and cost compared to ad hoc yet produces the same results, meeting the same goals.

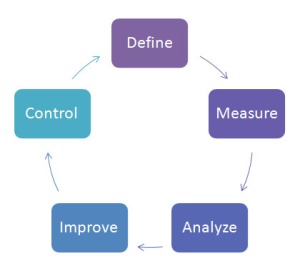

Lean analyzes business processes to identify waste. Waste is anything the customer (such as a CMO) wouldn’t want to pay for. We score each step in the process for its customer value. Processes are further refined to assure only customer-valued activities are being performed. Finally, kaizen is used for continual improvement.

Lean analyzes business processes to identify waste. Waste is anything the customer (such as a CMO) wouldn’t want to pay for. We score each step in the process for its customer value. Processes are further refined to assure only customer-valued activities are being performed. Finally, kaizen is used for continual improvement.

Lean initiatives are most successful in the service industry when combined with Six Sigma to form Lean Six Sigma. Taking on Six Sigma is a huge undertaking. I always recommend starting with the easier of the two (Lean), then introducing Six Sigma concepts when it makes sense to do so, and launching a full Six Sigma initiative after Lean is ingrained.

A common concern I’ve heard concerning Lean involves developing general rules for custom work. Analytical activities are rarely the same twice, every marketing effort is different, and goals are always evolving. There are three approaches to address these concerns. First, perhaps you only need to create standards around the common elements of activities. Second, apply the Pareto Principle: perhaps 80 percent of a job can be made the same each time, allowing 20 percent for flexibility. Third, standard Lean processes can be done cheaper, faster, consistently, and with high quality, which will discourage traditional inefficient activities. Given these three approaches, Lean can be applied to changing work environments.

The following are some quick tips to help get a Lean initiative started in your organization:

- As with every initiative, you need upper management’s buy-in. Upper management should perform Lean training events and help guide Lean activities.

- Find a Sensei who will advise senior management, have an enterprise-wide view on the initiative, and be a resource for project teams as they work through Lean concepts.

- Pick a quick-win project for Lean, then line up several more projects to follow. The lessons learned from one project will quickly spill into surrounding projects, creating a wildfire effect. Feed the wildfire by increasing the number of people involved and the numbers of projects that will receive the time investments to perform the Lean activities.

- When picking a project, train the entire project team and anyone who touches the project in a significant way. As more projects are “Leaned,” you’ll find teams with veterans who don’t need training and can help coach others.

- The project manager (coached by the sensei) will drive the Lean activities within the project. As the organization becomes proficient with Lean, it will become normal business practice, and project managers will dedicate less time to guiding Lean within their projects.

- As processes are improved, they should be shared with other project teams through a common repository. Adopting new and better ways of doing things should be encouraged and rewarded.

Lean allows organizations to understand their business processes and streamline toward customer value. Productivity will increase, costs will decrease, work backlogs will decrease, and customer value will rise. If your organization is facing difficult times due to a challenging economy, Lean may be a perfect way to gain productivity.

About the Author:

Kevin Gilbert is the Technology Manager at SIGMA Marketing Group and has been a Lean Sensi since 2005. He is a certified Six Sigma Lean Certified Project Manager. Connect with Kevin on .

{ 1 trackback }